When it comes to industrial packaging, using reliable and sturdy packaging materials that can keep the products safe and contamination-free is imperative. Furthermore, with organic minerals and dangerous chemicals often making a part of bulk dry goods, there is usually a long list of safety regulations to be followed.

Flexible Intermediate Bulk Containers (FIBCs) tick all these boxes quite effectively. They not only make storing and transporting easier but also play a pivotal role in reducing shipping costs. By eliminating the need for secondary packaging, enduring large quantities and creating an extremely low dead weight, FIBCs take care of transit costs in more ways than one.

Commonly, there are 4 variants of FIBCs – A, B, C and D, defined by the construction of the bags, their intended use as well as performance criteria. And then there is the UN-certified FIBC calling for specific requirements and rigorous testing.

In this two-part series, let’s deep dive into some of the crucial aspects of UN-certified FIBCs. Let’s begin…

What Are UN Certified FIBCs?

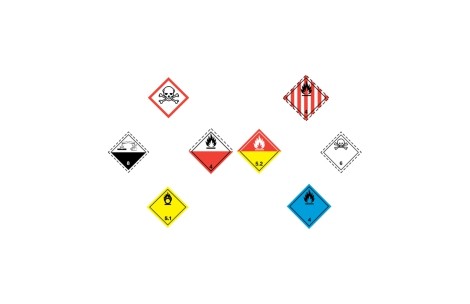

A United Nations-certified FIBC is essentially a bulk bag designed to transport and store hazardous materials. These toxic, flammable, combustible, or environmentally harmful materials need to be transported as per the guidelines assigned to them by the UN’s Orange Book. [1]

But what makes UN-certified FIBCs different from other FIBCs is the series of performance tests that they undergo before they can be certified so. A UN-rated FIBC has to adhere to strict marking and labelling requirements in order to prevent and minimize the risk of causing serious harm to the public or the environment.

Accordingly, UN-certified FIBCs typically have a higher Safety Factor (SF) of 8:1 than your standard bulk bags. The top, base and body are made sturdier to pass the Topple and Righting Tests that really dial in on the bag’s reliability in adverse conditions.

In a numbers game, UN-certified bulk bags must carry a minimum of 6:1 Safety Factor (SF), while standard FIBCs only need 5:1 SF for regular use. To pass this high ratio, the FIBC needs to endure 70 press-and-release top lift cycles at around 4x the bag’s Safe Working Load (SWL), only to be followed by a final cycle at 6x SWL.

Understanding The Performance Tests For UN Certification

Preparation

For consistency purposes, a standard needs to be maintained while testing each bag. Proper bulk bag preparation includes the following prerequisites:

- The bag must be filled to at least 95% capacity

- Contents need to be evenly distributed in the bag

- The same material that is to be transported or a similar non-hazardous one that holds the same physical characteristics should be used while testing

In the second part of this two-part series, let’s look at the 6 types of performance tests for an FIBC to be qualified as an UN-certified FIBC.

In the meantime, please feel free to reach out to us at sales.export@emmbi.com if you have any questions.

References

[1] UN’s Orange Book – https://unece.org/DAM/trans/doc/2010/ac10c3/ST-SG-AC10-C3-2010-88e.doc