Storage and transportation of bulk materials in Standard FIBC not only

takes more space but also leads to higher space utilisation in containers &

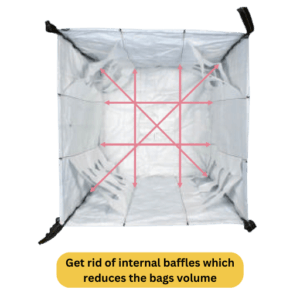

Trucks. Companies generally use Baffle Bags to maintain the shape which

requires more stitching and more Polymer usage.

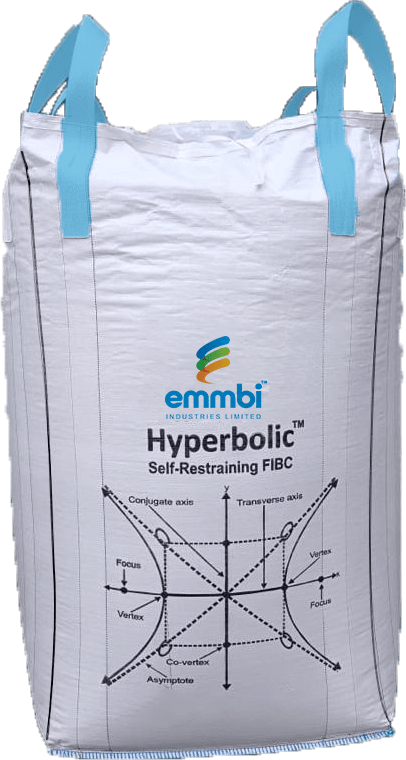

To resolve this issue, Emmbi has developed HyperbolicTM technology that

offers specially weaved fabric to handle the out-ward forces by reducing the

impact of the perpendicular force on the walls of the filled FIBC which

results in a Hyperbolic shape without the use of internal baffles. Hyperbolic

FIBCs accurately fits on pallets with stability and optimise storage space.