Space optimization is one of the most critical storage, warehousing, and transportation objectives.

Baffle bags are flexible intermediate bulk container bags designed to optimize storage, warehousing, and transportation space.

These are specially designed baffle bags that reduce bulging and maintain cube-like shapes.

Space Confignment range

They help optimize filling space utilization and proper flow of the filling material. While other manufacturers offer a single standard baffle bag, Emmbi is the only company that offers eight distinct types of Baffle Bags. These types are:

1. Standard All Panel Baffle Bag

Standard all panel baffle bags have a simple cubic construction, providing optimum space utilization and preventing bulges.

The baffles inside the bag connect all four sides of the fibc and offer the perfect balance and keep the bag bulge-free.

2. Net Baffle Bags

Emmbi, one of the leading flexible intermediate bulk containers manufacturers, offers Net Baffles bags that are specially designed space confinement bags that enable even the most minor flowing products to flow directly to the corners of the formed bag. These bags feature superior construction standards using corner net baffles to successfully maintain their cubic form once these are filled and allow material to flow smoothly into all corners, yet preventing bags from expanding in the process. Net baffle bags are suitable to pack less flowy, lumpy and sticky products.

3. Circular Baffle Bags

These bags are cost-effective in storing powdered materials.

Emmbi’s Circular Baffle bags are specially designed space optimization bags with fewer seams that enable them to carry fine powders. In addition to this, they can also hold materials with high bulk density. These bags are bulge-free and maintain a cube-like shape which helps in optimizing filling space utilization and proper discharge of the materials stored inside.

4. Gambo Liner Baffle Bags

Gambo liner baffle bags are cuboid FIBC bags that provide the highest sift-proof resistance. The bag structure comprises a low GSM PP liner stitched inside a regular four-loop baffle bag where the liner acts as a baffle bag and creates a double-walled design, ensuring that the bags are easily stackable.

These are suitable for companies with an increased focus on good printing & to improve the container load-carrying ability.

5. Pinch Edges Baffle Bags

Pinch edges baffle bags are flexible intermediate bulk containers that are highly effective for storing and transporting lumpy and bulky products other than those in powdered form. They are long and have a bell-like bottom that provides maximum stability during transport.

6. Belly Band Baffle Bags

Belly Band Baffle bag offers Precision bulge control & a cost-effective solution for materials with very high bulk density above 1.2. Belly Bands can be placed at the 3/4th From top, Centre and 1/4th from the bottom of the bags.

7. Baffle Liners

Emmbi’s Baffle liners are specially designed to store and transport hygroscopic materials, i.e., materials that tend to absorb moisture from the air. They are manufactured with built-in baffles in the liner instead of the FIBC. Baffle liners occupy minimal space during the storage of goods by maintaining a square shape, reducing the bulging and maintaining a cube-like shape.

Baffle Liners provide high package performance and can reduce storage and shipping costs and, in some cases, reduce the outer package’s cost.

The Emmbi Advantage:

Emmbi’s FIBC Containers offer the below-listed unique features:

- High-Quality Manufacturing Standards

- Variety Of Baffle Bags That Suit Various Applications

- Global Products That Meet The Highest Safety Standards

Handling Instructions For Baffle Bags:

- Ensure to use all four straps

- Avoid any jerking motion

- Avoid contact with forklift body

- Never drag the containers

- Avoid prolonged contact with temperatures above 60 degrees centigrade

- Avoid contact with sharp objects

Product Variations

All Panel Baffle

The essence of this bag is to reduce bulge at the belly of bag which creates a perfect cube-like structure. This helps to optimize filling space utilization and to save cargo space as well.

Application

Maximum utilization of space during transportation.

Circular baffle

These bags have less number of seams which make them suitable to carry fine powders. They can also carry materials with high bulk density.

Application

Fine powders.

Pinched Edges

These are economical bags made for lower safe working load. They are used for low density materials of less than 0.4.

Application

Lumpy/bulky materials.

Net Baffles

These bags are useful to fill materials which have less flow.

Application

Lumpy/bulky materials.

Baffle Liners

These are lined for moisture proofing of hygroscopic materials.

Application

Hygroscopic materials.

Gambo liner

This is an extended version of a normal baffle FIBC. A low GSM PP liner is stitched inside a regular four loop bag. This liner acts like a baffle bag itself. The double walled structure helps the bag to be more friendly with stacking. These are best used when the cost of transportation is very high.

Application

Very fine powder.

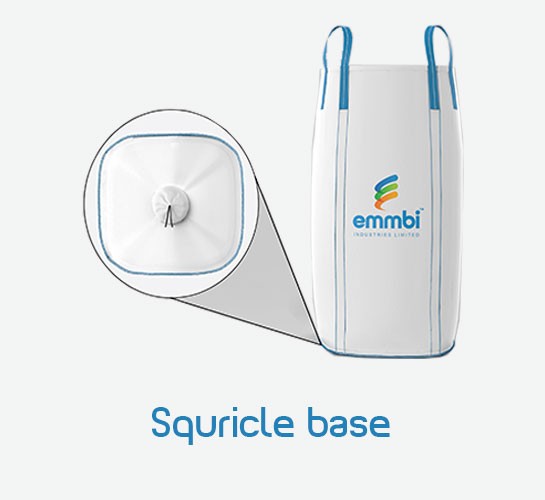

Squircle Baffle

Squircle Bag acts like baffle to keep the bag from bulging. These are used for low density materials.

Application

Very fine powder.

Belly Band

Belly Band Baffle bag offers Precision bulge control & cost effective solution for materials that have very high bulk density above 1.2

Application

Maximum utilization of space during transportation

More Products

Dewatering FIBC

In many cases the need of “Quick Solid – Liquid” separation is always felt by many industries. These bags are made using a specially designed porous fabric which will let the liquid of viscosity above 30 m2/ sec quickly pass through creating a filtration effect. These bags are perfect for “Mud-Water” separation on construction site. “Sludge-Oil” separation on the rig’s and oil slicks.

Self standing FIBC

These are a good alternative for rigid containers. Self standing FIBCs are collapsible and can be used in spaces with less height.